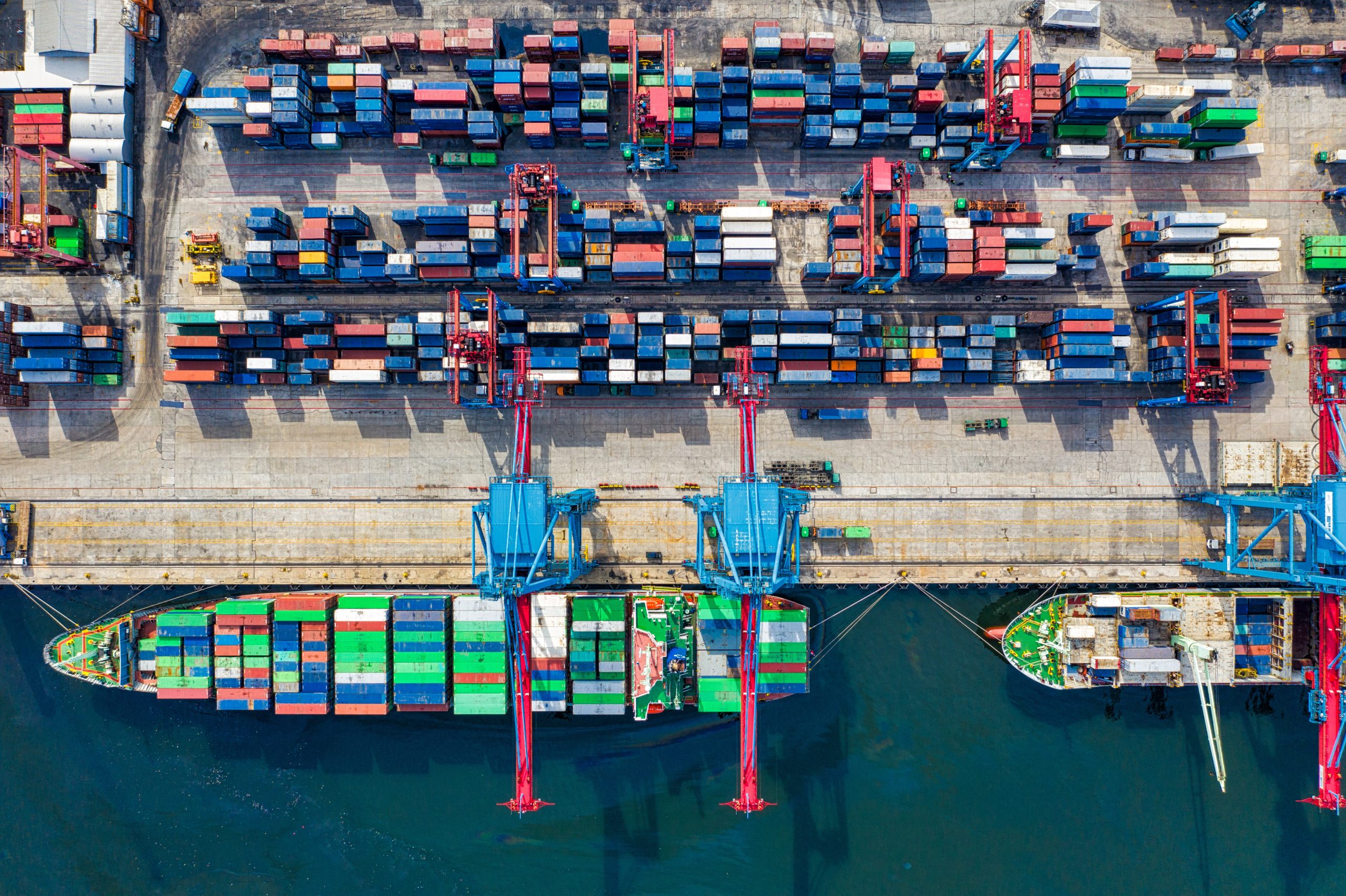

Supply Chain Management

What is Supply Chain Management

Supply chain management is the management of the flow of goods and services

and includes all processes that transform raw materials into final products.

Supply chain management deals all movement and storage of raw materials,

work-in-process inventory, and finished goods from point-of-origin to point-of-consumption”.

- The term “supply chain management” was first coined

by Keith Oliver in 1982. However, the concept of a supply chain in management was of great

importance long before, in the early 20th century, especially with the creation of the

assembly line. The characteristics of this era of supply-chain management include the need

for large-scale changes, re-engineering, downsizing driven by Cost

Reduction programs, and widespread attention to Japanese management practices.

- The SCM evolved further with the development of

Enterprise Resource Planning ( ERP) & Electronic Data Interchange (EDI) where the other

dept like manufacturing, distribution , storage were linked . This enabled the SCM to

develop further and reduce cost and improve process.

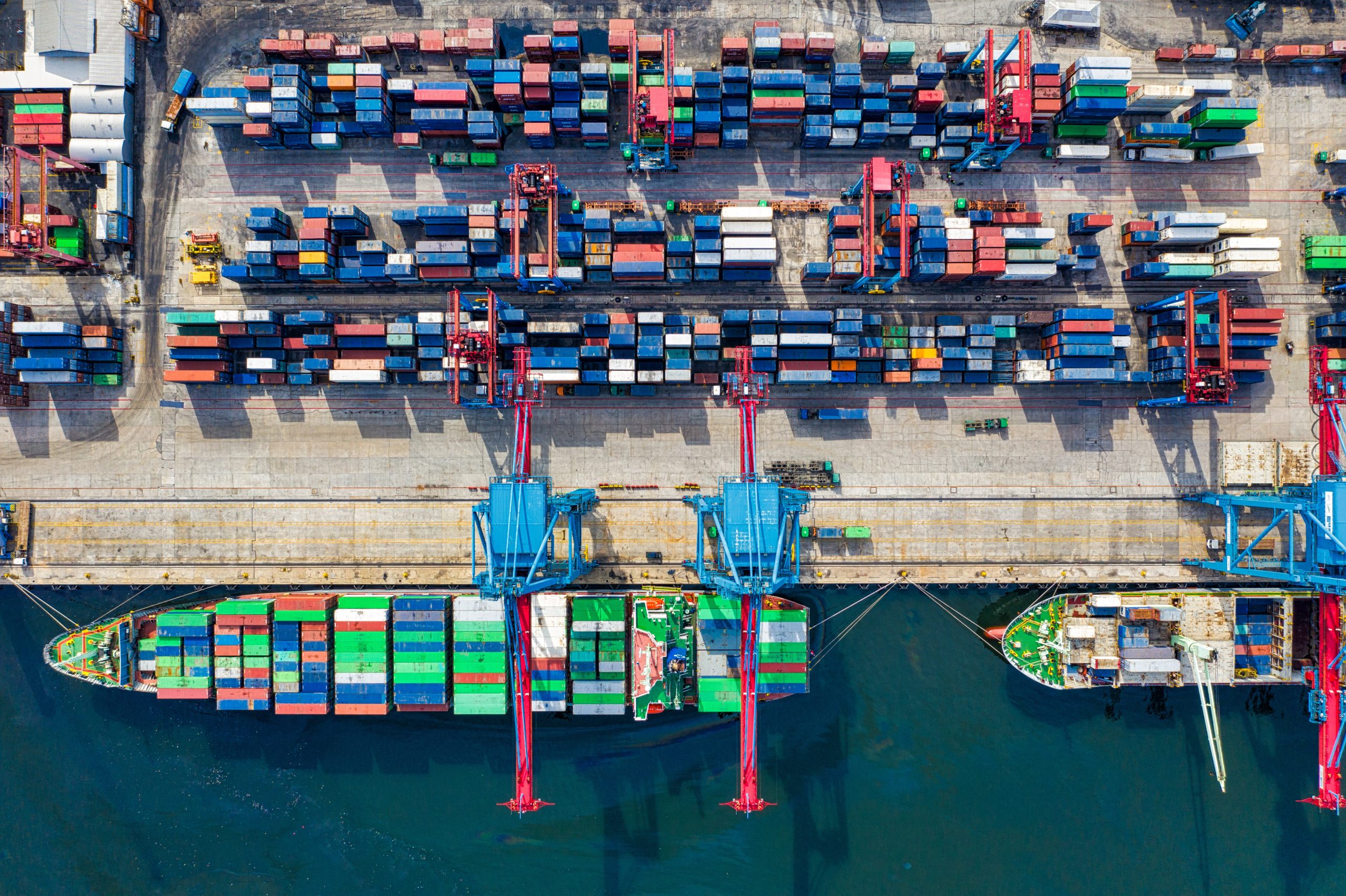

- It is the third movement of supply-chain-management

development, the globalization era, can be characterized by the attention given to global

systems of supplier relationships and the expansion of supply chains beyond national

boundaries and into other continents. Although the use of global sources in organizations’

supply chains can be traced back several decades (e.g., in the oil industry), it was not

until the late 1980s that a considerable number of organizations started to integrate global

sources into their core business. This era is characterized by the globalization of

supply-chain management in organizations with the goal of increasing their competitive

advantage, adding value, and reducing costs through global sourcing

- In the 1990s, companies began to focus on “core

competencies” and specialization. They abandoned vertical integration, sold off non-core

operations, and outsourced those functions to other companies. This changed management

requirements, as the supply chain extended beyond the company walls and management was

distributed across specialized supply-chain partnerships.

- Original Equipment manufacturers became brand owners

that required visibility deep into their supply base. They had to control the entire supply

chain from above, instead of from within. Contract manufacturers had to manage bills of

material with different part-numbering schemes from multiple OEMs and support customer

requests for work-in-process visibility and VMI.

- The specialization model creates manufacturing and

distribution networks composed of several individual supply chains specific to producers,

suppliers, and customers that work together to design, manufacture, distribute, market,

sell, and service a product. This set of partners may change according to a given market,

region, or channel, resulting in a proliferation of trading partner environments, each with

its own unique characteristics and demands

Supply-chain management 2.0 (SCM 2.0):-

Building on globalization and specialization, the term “SCM 2.0” has been

coined to describe both changes within supply chains themselves as well as the evolution of

processes, methods, and tools to manage them in this new “era”.

SCM is the combination of processes, methodologies, tools, and delivery options

to guide companies to their results quickly as the complexity and speed of the supply-chain increase

due to global competition; rapid price fluctuations; changing oil prices; short product life cycles.

The supply chain management provider not only list the services for users to access, but also other

relevant services such as monitor the warehouse and logistics.